MAIN PUBLICATION :

| Home � TECHNOLOGY � Wind farm design � Infrastructure |

|

Infrastructure

The wind farm infrastructure consists of:

- Civil works:

- Roads and drainage;

- Wind turbine foundations;

- Met mast foundations (and occasionally also the met masts); and

- Buildings housing electrical switchgear, SCADA central equipment, and possibly spares and maintenance facilities.

- Electrical works:

- Equipment at the point of connection (POC), whether owned by the wind farm or by the electricity network operator;

- Underground cable networks and/or overhead lines, forming radial ‘feeder’ circuits to strings of wind turbines;

- Electrical switchgear for protection and disconnection of the feeder circuits;

- Transformers and switchgear associated with individual turbines (although this is now commonly located within the turbine and is supplied by the turbine supplier);

- Reactive compensation equipment, if necessary; and

- Earth (grounding) electrodes and systems.

- Supervisory Control and Data Acquisition (SCADA) system:

- Central computer;

- Signal cables to each turbine and met mast;

- Wind speed and other meteorological transducers on met masts; and

- Electrical transducers at or close to the POC.

The civil and electrical works are often referred to as the Balance of Plant (BOP). The civil and electrical works are often designed and installed by a contractor or contractors separate from the turbine supplier. The turbine supplier usually provides the SCADA system, apart from the cables which are normally supplied and installed by the electrical contractor.

As discussed above, the major influence on the economic success of a wind farm is the energy production, which is principally determined by the wind regime at the chosen site, the wind farm layout and the choice of wind turbine. However, the wind farm infrastructure is also significant, for the following reasons:

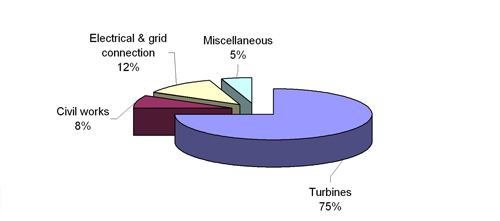

- The infrastructure constitutes a significant part of the overall project cost. A typical cost breakdown is given in Figure I.4.7.

- The civil works present significant risks to the project costs and programme. It is not unknown for major delays and cost overruns to be caused by poor understanding of ground conditions, or the difficulties of working on sites that, by definition, are exposed to the weather and may have difficult access.

- The major electrical items (transformers, switchgear) have long lead times. At the time of writing, a large HV/MV power transformer may have a lead time of several years.

- The grid connection works may present a significant risk to the programme. It is likely that works will need to be undertaken by the electricity network operator, and the programme for these works is effectively out of the control of the wind farm developer. It is very unusual for electricity network operators to accept liability for any delay.

Figure I.4.7: Typical Cost Breakdown for an Onshore Wind Farm

Source: Garrad Hassan

| Civil works >> |

| Acknowledgements | Sitemap | Partners | Disclaimer | Contact | ||

|

coordinated by  |

supported by  |

The sole responsibility for the content of this webpage lies with the authors. It does not necessarily reflect the opinion of the European Communities. The European Commission is not responsible for any use that maybe made of the information contained therein. |