MAIN PUBLICATION :

| Home � TECHNOLOGY � Wind Turbine Technology � Current developments |

|

Current Developments

Rotor Blade Development

LARGE BLADE DESIGN

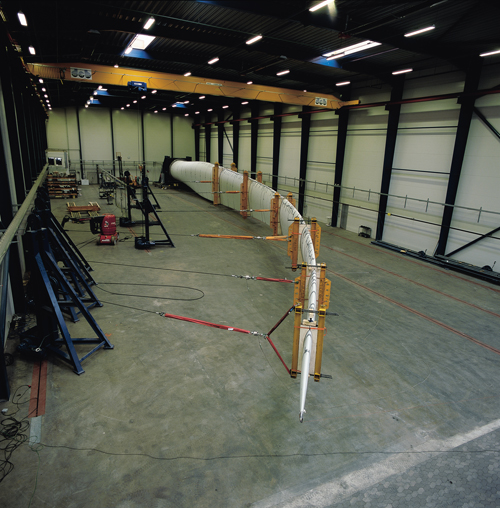

Development in materials for rotor blades is ongoing. Testing ranging from characterisation of constituent materials, through blade sub-components to whole blades is vital for the integrity of new designs. As the wind industry has matured, proof testing, ultimate load testing and fatigue testing of new rotor blade designs has become the norm. Figure 3.29 shows blade testing at LM Glasfiber, which have long been the world’s largest independent blade supplier. The commitment of LM Glasfiber to blade development for wind turbines is shown by a recent investment in their own specially designed wind tunnel, which can provide tunnel speeds up to 105 m/s and test an airfoil with 0.90m chord at Reynolds number up to 6 million.

Figure 3.29: LM Glasfiber Blade Test (LM 61.5m Blade for 126m Rotor Diameter)

Source: LM Glasfiber

The handling and transport issues with very large blades have caused some manufacturers to revisit ideas for jointed blades.

The world’s largest wind turbine, the Enercon E126, adopts a jointed blade design. In the E126 blade, an essentially standard outer blade section with a conventional blade root attachment is bolted to a steel inner blade spar. The trailing edge of the inner blade is a separate composite structure. Gamesa has also developed a jointed blade design for the G10X.

Enercon has been pushing the limits in maximum attainable aerodynamic performance of a horizontal axis wind turbine rotor, in achieving a measured rotor power performance coefficient in excess of 0.5. It may be noted that its recent designs take great care to manage the flow regime in the region of the hub and also employ winglets, which are suggested by research at Risø to reduce power loss associated with the blade tip effect.

PITCH SYSTEMS

The Genesys 600 kW direct drive wind turbine, on which the Vensys designs are based, employed almost wear-free toothed belts in the pitch drives, instead of the more common hydraulic cylinders or geared electric pitch motors. One key advantage claimed for this innovation is insensitivity to shock loads, since such impact forces are distributed over multiple meshing teeth pairs. A second advantage is that the drive system does not require grease lubrication and is almost maintenance free. Toothed belts are widely used in industrial and automotive applications. Vensys have maintained this feature in their present designs.

| Alternative drive train configurations >> |

| Acknowledgements | Sitemap | Partners | Disclaimer | Contact | ||

|

coordinated by  |

supported by  |

The sole responsibility for the content of this webpage lies with the authors. It does not necessarily reflect the opinion of the European Communities. The European Commission is not responsible for any use that maybe made of the information contained therein. |