MAIN PUBLICATION :

| Home � ENVIRONMENT � Environmental benefits � LCA in wind energy |

|

LCA in Wind Energy: Environmental Impacts through the Whole Chain

The LCA approach provides a conceptual framework for a detailed and comprehensive comparative evaluation of environmental impacts as important sustainability indicators.

Recently, several LCAs have been conducted to evaluate the environmental impact of wind energy. Different studies may use different assumptions and methodologies, and this could produce important discrepancies in the results among them. However, the comparison with other sources of energy generation can provide a clear picture about the environmental comparative performance of wind energy.

An LCA considers not only the direct emissions from wind farm construction, operation and dismantling, but also the environmental burdens and resources requirement associated with the entire lifetime of all relevant upstream and downstream processes within the energy chain. Furthermore, an LCA permits quantifying the contribution of the different life stages of a wind farm to the priority environmental problems.

Wind energy LCAs are usually divided into five phases:

- Construction comprises the raw material production (concrete, aluminium, steel, glass fibre and so on) needed to manufacture the tower, nacelle, hub, blades, foundations and grid connection cables.

- On-site erection and assembling includes the work of erecting the wind turbine. This stage used to be included in the construction or transport phases.

- Transport takes into account the transportation systems needed to provide the raw materials to produce the different components of the wind turbine, the transport of turbine components to the wind farm site and transport during operation.

- Operation is related to the maintenance of the turbines, including oil changes, lubrication and transport for maintenance, usually by truck in an onshore scheme.

- Dismantling: once the wind turbine is out of service, the works of dismantling the turbines and the transportation (by truck) from the erection area to the final disposal site; the current scenario includes recycling some components, depositing inert components in landfills and recovering other material such as lubricant oil.

ONSHORE

Vestas Wind Systems (Vestas, 2005 and 2006) conducted several LCAs of onshore and offshore wind farms based on both 2MW and 3MW turbines. The purpose of the LCAs was to establish a basis for assessment of environmental improvement possibilities for wind farms through their life cycles.

Within the framework of the EC project entitled 'Environmental and ecological life-cycle inventories for present and future power systems in Europe' (ECLIPSE), several LCAs of different wind farm configurations were performed. The technologies studied in ECLIPSE were chosen in order to be representative of the most widely used wind turbines. Nevertheless, a wide range of the existing technological choices were studied:

- Four different sizes of wind turbines: 600 kW (used in turbulent wind conditions), 1,500kW, 2,500 kW and 4,500 kW (at the prototype stage);

- A configuration with a gearbox and a direct drive configuration, which might be developed in the offshore context;

- Two different kinds of towers: tubular or lattice; and

- Different choices of foundations, most specifically in the offshore context.

Within the EC project NEEDS (New energy externalities development for sustainability), life cycle inventories of off-shore wind technology were developed along with several other electricity generating technologies. The wind LCA focused on the present and long-term technological evolution of offshore wind power plants. The reference technology for the present wind energy technology was 2MW turbines with three-blade upwind pitch-regulation, horizontal axis and monopile foundations. An 80-wind-turbine wind farm located 14 km off the coast was chosen as being representative of the contemporary European offshore wind farm.

In the framework of the EC project 'Cost Assessment for Sustainable Energy Systems' (CASES), an estimation of the quantity of pollutants emitted at each production stage per unit of electricity for several electricity generation technologies, among them onshore and offshore wind farms, is performed.

Finally, the Ecoinvent v2.0 database (Jungbluth 2007) includes LCA data of several electricity generation technologies including an onshore wind farm using 800kw turbines and an offshore wind farm using 2MW turbines.

LCI Results: Onshore Wind Farms

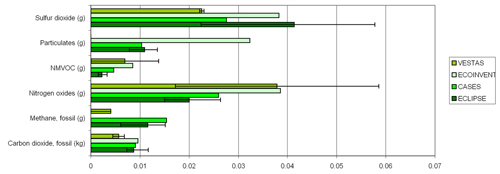

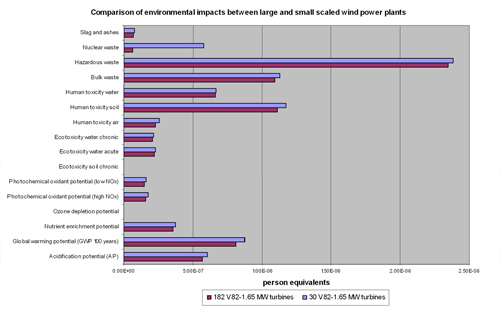

Results extracted from the above mentioned LCA studies for onshore wind farms regarding several of the most important emissions are shown in Figure 1.2. Bars show the variability of the results when several wind farm configurations are considered in a study.

Carbon dioxide emissions vary from 5.6 to 9.6 g/kWh in the consulted references. Methane emissions range from 11.6 to 15.4 mg/kWh. Nitrogen oxides emissions range from 20 to 38.6 mg/kWh. Non-methane volatile organic compounds are emitted in quantities that range from 2.2 to 8.5 mg/kWh, particulates range from 10.3 to 32.3 mg/kWh and, finally, sulphur dioxide emissions range from 22.5 to 41.4 mg/kWh. All of these quantities, with the only exception being particulates, are far below the emissions of conventional technologies such as natural gas (see Figure 1.2).

Figure 1.2. Emissions from the Production of 1 kWh in Onshore Wind Farms Throughout the Whole Life Cycle

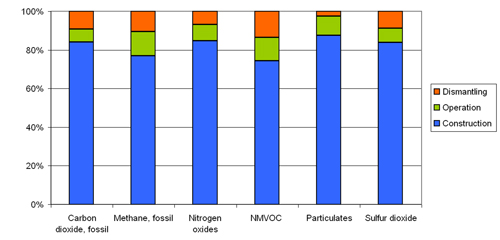

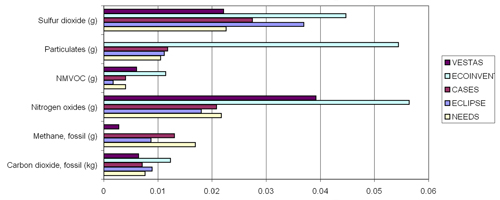

Another main outcome of all the reviewed studies is that the construction phase is the main contributor to the emissions and hence the environmental impacts. As can be observed in Figure 1.3, the construction phase causes about 80 per cent of the emissions. The operational stage, including the maintenance and replacement of materials, is responsible for 7-12 per cent of the emissions, and the end-of-the-life of the wind farm is responsible for 3-14 per cent.

Figure 1.3. Contribution of the Different Life Cycle Phases to the Relevant Emissions

Source: Own elaboration using ECLIPSE results

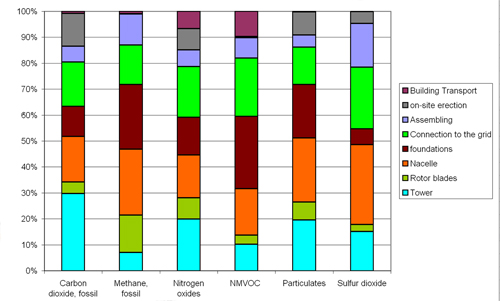

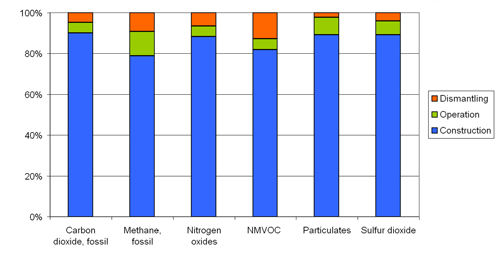

Regarding the construction stage, Figure 1.4 shows the contribution of the different components. Important items in the environmental impacts of the construction phase of an onshore wind farm are the tower and the nacelle but not the rotor blades. Foundations are another important source of emissions, and connection to the grid also contributes an important share. Emissions from transport activities during the construction phase are only relevant in the case of NOx and NMVOC emissions.

Figure 1.4. Contribution of the components of the construction phase to the different emissions

Source: Own elaboration based on ECLIPSE results

LCA Results: Onshore Wind Farms

Results of LCAs have shown wind farm construction is the most crucial phase because it generates the biggest environmental impacts. These impacts are due to the production of raw materials, mostly steel, concrete and aluminium, which are very intensive in energy consumption. The energy production phase from wind is clean because no emissions are released from the turbine.

LCAs have also concluded that environmental impacts from the transportation and operation stages are not significant in comparison with the total impacts of the wind energy.

The contribution of the different stages to the ICs selected by the LCA of the Vestas V82 1.65 MW wind turbine is shown in the Figure 1.5.

Figure 1.5. Environmental Impacts by Stages from 1 kWh

Courtesy of Vestas Wind System A/S

In the Vestas study, the disposal scenario involves the dismantling and removal phases. Thus negative loads of recycling must be deducted, since some materials are returned to the technosphere. The disposal scenarios considered have great influence on the results.

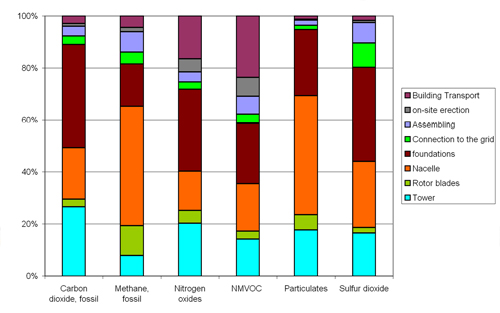

This study evaluated the influence of small- and large-scale wind power plants on the environmental impacts based on the V82 1.65 MW wind turbine. According to Figure 1.6, a variation in the size of the wind power plant from 182 to 30 turbines did not produce significant changes in the environmental impacts.

Figure 1.6. Comparison of Environmental Impacts by Number of Wind Turbines

Courtesy of Vestas Wind System A/S

OFFSHORE

LCI Results: Offshore Wind Farms

Results extracted from the reviewed LCA studies for offshore wind farms regarding several of the most relevant emissions are shown in Figure 1.7. Bars show the variability of the results when several wind farm configurations are considered in a single study.

Carbon dioxide emissions vary from 6.4 to 12.3 g/kWh in the consulted references. Methane emissions range from 2.8 to 16.9 mg/kWh. Nitrogen oxides emissions range from 18 to 56.4 mg/kWh. NMVOCs are emitted in quantities that range from 1.7 to 11.4 mg/kWh, particulates range from 10.5 to 54.4 mg/kWh and, finally, sulphur dioxide emissions range from 22.1 to 44.7 mg/kWh. All of these quantities, are quite similar to those obtained for onshore wind farms, with the only exception being that particulates are far below the emissions of conventional technologies such as natural gas (see Figure 1.7).

Figure 1.7. Emissions from the Production of 1kWh in Offshore Wind Farms Throughout the Whole Life Cycle

In Figure 1.8, the contribution of different life cycle phases to the emissions is depicted. In an offshore context, the contribution of the construction phase is even more important, accounting for around 85 per cent of the emissions and hence of the impacts.

Figure 1.8. Contribution of the Different Life Cycle Phases of an Offshore Wind Farm to the Relevant Emissions

Source: Own elaboration using ECLIPSE results

Within the construction stage, Figure 1.9 shows the contribution of the different components. Important items in the environmental impacts of the construction phase of an offshore wind farm are the nacelle and the foundations followed by the tower. The rotor blades are not found to play an important part. Emissions from transport activities during construction phase are quite relevant in the case of NOx and NMVOCs emissions.

Figure 1.9: Contribution of the Components of the Construction Phase to the Different Emissions

Source: Own elaboration using ECLIPSE results

LCA Results: Offshore Wind Farms

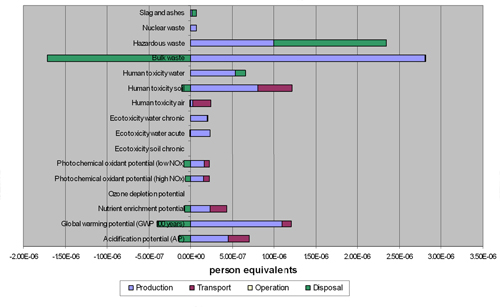

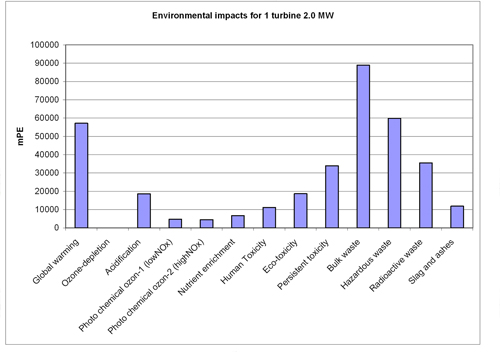

As far as offshore technology is concerned, Vestas Wind Systems A/S and Tech-wise A/S on behalf of Elsam A/S have developed a project titled: 'LCA and Turbines'. The goal of the project was to create a life-cycle model for a large Vestas offshore turbine. Based on this offshore model, an analysis was carried out to identify the most significant environmental impacts of a turbine during its life cycle. (Elsam-Vestas, 2004). Environmental impacts can be seen in Figure 1.10.

Figure 1.10. Environmental Impacts of Vestas 2.0 MW

Courtesy of Vestas Wind System A/S

Results showed that the volume of waste is the largest normalised impact from a turbine. The bulk of waste is produced during the manufacturing phase, primarily from the steel production needed for the foundation and the tower.

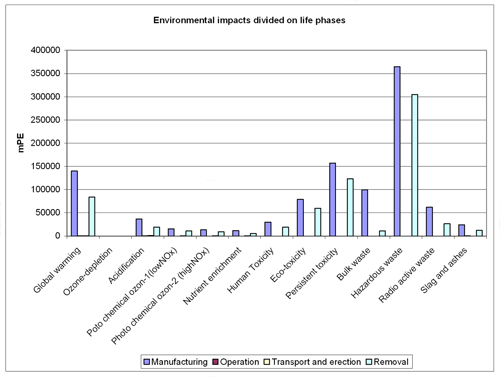

The environmental impacts of the life phases and component systems are illustrated in Figure 1.11. The largest environmental impacts are found in the manufacturing phase. The disposal scenario makes a very important contribution to the entire environmental impact. In the disposal scenario, about 90 per cent of the steel and iron could be recycled while 95 per cent of the copper could be recycled. With less recycling, there is more waste. The other two life phases (operation and removal) do no contribute significantly to the environmental impacts.

Figure 1.11. Contribution of Environmental Impacts by Life Cycle Stages. Vestas 2.0 MW

Courtesy of Vestas Wind System A/S

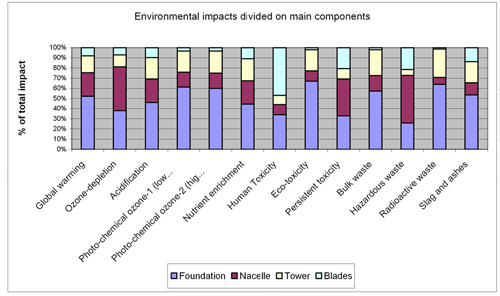

The environmental impacts produced from the manufacturing phase by components shows that the foundation has the highest contribution to several impact categories. Tower and nacelle manufacturing also have a significant contribution. The impacts distribution is showed in Figure 1.12.

Figure 1.12. Contribution of the Components of the Construction Phase to the Different Impacts

Courtesy of Vestas Wind System A/S

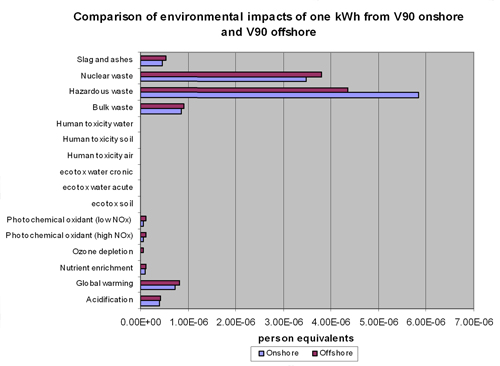

A comparison between the onshore and offshore impact of the very same wind turbine (a Vestas V90. 3.0 MW) was carried out by Vestas. Results of this LCA show similar environmental profiles in both cases. However, offshore wind turbines produce more electricity (11,300 - 14,800 MWh/turbine) than onshore wind turbines (6,900 - 9,100 MWh/turbine). However, offshore turbines are more resource demanding. Thus these two parameters are offset in some cases.

Figure 1.13. Onshore-Offshore Comparison of Environmental Impacts

Courtesy of Vestas Wind System A/S

| Acknowledgements | Sitemap | Partners | Disclaimer | Contact | ||

|

coordinated by  |

supported by  |

The sole responsibility for the content of this webpage lies with the authors. It does not necessarily reflect the opinion of the European Communities. The European Commission is not responsible for any use that maybe made of the information contained therein. |